Water plugging airbag for home PVC pipeline repair

1. What is a Water Plugging Airbag?

2. Key Selection Criteria for Home Use

2.1 Pipe Diameter Matching

PVC Pipe Diameter | Recommended Airbag Model | Inflation Pressure | Weight |

50mm | HX50-A | 0.15 MPa | 0.015kg |

75mm | HX75-A | 0.15 MPa | 0.020kg |

110mm | HX100-A | 0.15 MPa | 0.32kg |

Note: Never use a smaller airbag for a larger pipe (risk of failure). |

2.2 Material Compatibility

Enhanced Natural Rubber: Best for general PVC pipes (corrosion-resistant, flexible, reusable).

TPU Composite: For long-term use (2-year lifespan) and acidic wastewater pipes.

Avoid recycled rubber products (poor airtightness).

2.3 Pressure Rating

3. Step-by-Step Operation Guide

3.1 Pre-Operation Preparation

Inspect the Airbag: Inflate to 0.15MPa with a hand pump; check for leaks using soapy water.

Clean the Pipe: Remove debris, burrs, or sharp objects (prevents punctures).

Assemble Tools: Connect airbag → pressure gauge → 6m air hose → pump.

3.2 Installation & Inflation

Insert the Airbag: Roll it vertically and place 30cm away from pipe joints/elbows (joints reduce sealing performance).

Secure Connections: Tie the air hose to the airbag with wire (prevents detachment).

Inflate Gradually:

Start with slow inflation (0.05MPa/min)

Stop at the recommended pressure (e.g., 0.25MPa for 110mm pipes)

Monitor the gauge—rapid pressure spikes indicate blockage (release air immediately).

3.3 Post-Repair Removal

Deflate completely (open the air valve for 2 minutes)

Pull out gently (avoid dragging to prevent scratches)

Clean with water and store in a dry, cool place.

4. Safety & Maintenance Tips

Pressure Limits: Never exceed 0.3MPa (risk of bursting); check pressure hourly during repairs.

Pipe Protection: Do not use on pipes with cracks or uneven inner walls (may cause airbag damage).

Lifespan Management: Replace natural rubber airbags every 12 months; TPU models every 2 years.

Emergency Handling: If pressure drops suddenly, stop work and repressurize—leaks often occur at hose connections.

5. Top Recommendations for Home Use

Brand | Model | Price Range | Key Advantage |

Fuli | 110# | (15–)30 | Acid-resistant, compact design |

Jerry Borg | HX100-A | (30–)50 | High-pressure resistance |

Generic | PVC Valve Airbag | (8–)15 | Budget-friendly for small pipes |

Source: Manufacturers’ data & market listings |

Recently Posted

-

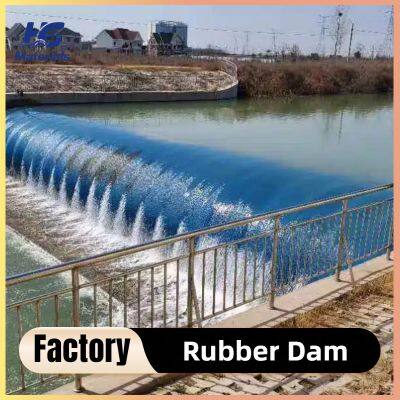

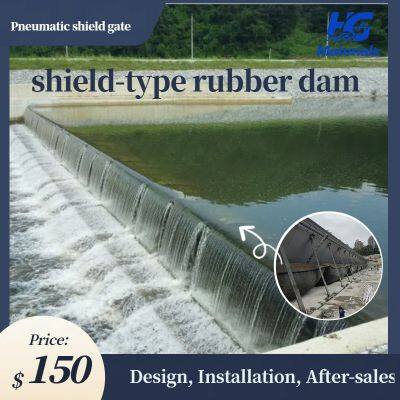

Cost of Pneumatic Shield Dam

December 20, 2025Pneumatic Shield Gate (PSG) has become a preferred water control solution in various hydraulic and water conservancy projects due Read More

Read More -

Advantages of Pneumatic Shield Gate (PSG)

December 20, 2025Advantages of Pneumatic Shield Gate (PSG)Pneumatic Shield Gate (PSG) has become a preferred water control solution in various hydr Read More

Read More -

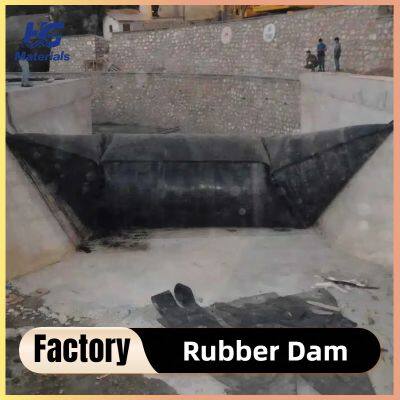

Components of Pneumatic Shield Gate (PSG)

December 20, 2025Common River Channel Forms of Pneumatic Dams (Pneumatic Shields Rubber Dam)Pneumatic Shield Gate (PSG) is a composite water contro Read More

Read More -

Common River Channel Forms of Pneumatic Dams(Pneumatic Shields Rubber Dam)

December 20, 2025Common River Channel Forms of Pneumatic Dams(Pneumatic Shields Rubber Dam)1. Single-Span Straight Pneumatic Shield DamStructural F Read More

Read More