Operational Instructions for Hydraulic Elevator Dam (HED)

Mr. Wendy

October 27, 2025

Operational Instructions for Hydraulic Elevator Dam (HED)

1. Pre-Operation Inspection

2. Startup Procedure

3. Operation Control

3.1 Lifting/Lowering the Panel (Manual Mode)

3.2 Automatic Operation

4. Shutdown Procedure

4.1 Normal Shutdown

4.2 Temporary Shutdown (Short Breaks)

5. Emergency Handling

6. Daily Maintenance

Share

Recently Posted

-

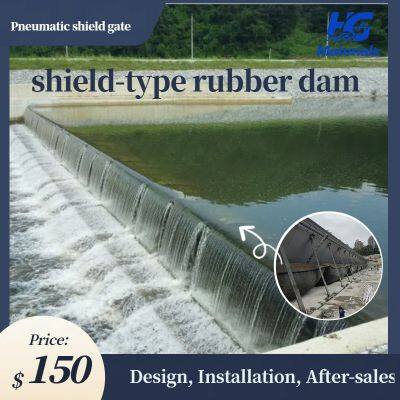

Cost of Pneumatic Shield Dam

December 20, 2025Pneumatic Shield Gate (PSG) has become a preferred water control solution in various hydraulic and water conservancy projects due Read More

Read More -

Advantages of Pneumatic Shield Gate (PSG)

December 20, 2025Advantages of Pneumatic Shield Gate (PSG)Pneumatic Shield Gate (PSG) has become a preferred water control solution in various hydr Read More

Read More -

Components of Pneumatic Shield Gate (PSG)

December 20, 2025Common River Channel Forms of Pneumatic Dams (Pneumatic Shields Rubber Dam)Pneumatic Shield Gate (PSG) is a composite water contro Read More

Read More -

Common River Channel Forms of Pneumatic Dams(Pneumatic Shields Rubber Dam)

December 20, 2025Common River Channel Forms of Pneumatic Dams(Pneumatic Shields Rubber Dam)1. Single-Span Straight Pneumatic Shield DamStructural F Read More

Read More